One of the key questions retailers ask themselves is how to improve stock management. Effective inventory management is a crucial aspect of successful business operations, which when done well, can lead to happier customers, better cash flow, and business growth.

Key Takeaways

- Understanding stock management

- Setting up a stock management system

- Managing inventory levels and optimising min & max stock levels based on seasonal demand

- Fine-tuning your forecasting for better inventory management

- Auditing and reviewing processes, and conducting regular stock takes

- Managing supplier relationships

- Training your team

- Integrating technology

- Reviewing and adjusting your stock control strategy

Understanding Stock Management

Effective stock control is crucial for retailers to maintain a solid financial position and drive profitability. Before we look at ways to improve stock management, we should first try and understand what good stock control includes:

- Good stock management is the process of planning, controlling, and organising your inventory to maintain optimal and committed stock levels throughout your sales curve, to meet customer demand.

- It involves tracking and analysing inventory data to make informed decisions about supply chain, stock control, and min and max inventory management.

Setting Up a Stock Management System

With a comprehensive stock management system, like Kudos, you can track your inventory from purchase order to sales, including stock allocation and transfers. Our user-friendly reporting and business intelligence allow buyers to get the right stock, in the right place, at the right time for effective inventory control across multiple locations and branches.

Investing in Inventory Management Software

Invest in an inventory management system that reflects the way you trade to track sales, streamline stock control processes, and improve stock rotation.

- Choose inventory software that provides real-time inventory tracking, automated reporting, and data analysis.

- Consider cloud-based inventory management solutions that integrate with your existing retail software.

Managing Inventory Levels

By replenishing stock, rotating displays, and using strategic promotions, shops can meet consumer demand, increase sales and improve customer experience. Software like Kudos can simplify operations and enhance the shopping experience. With the right technology, your team can manage your supply chain, sales order processing, stock allocations, transfers, tracking and pricing.

Optimising Stock Levels Based on Customer Demand

Implement a just-in-time (JIT) inventory system to minimise excess inventory, improve cash flow, save money and reduce waste, especially of seasonal or perishable goods with a limited shelf life. Optimise stock levels by analysing customer demand and sales curve data to reach optimal stock levels.

- Use inventory management software to track min and max stock levels and receive alerts when stock levels fall below a certain threshold and need replenishing.

- Track your newest Vs oldest stock, ensuring stock is rotated or warehoused for seasonal promotions.

- Maximise profit from efficient stock turn. This minimises static stock value and promotes fast-moving stock, so your stock investment is working harder for you.

Fine-Tune Your Forecasting for Better Inventory Management

Sales reports that produce meaningful data, such as sales trends by shop or by department, can help with optimising stock. For example, understanding how long to keep stock on rotation, by department, and understanding seasonal sales curve trends can boost your profitability and bottom line.

- Fine-tune your demand forecasting by analysing historical sales data, seasonality, and trends to predict future demand.

- Use stock management software to create accurate forecasts and adjust stock reorder levels accordingly.

- Use KPIs such as sales volume per store, per department, stock turn per sq. metre, average transaction value etc.

Stock turn is the gold standard for efficient stock holding and stock turn per square metre tells you how hard the stock is working on the shop floor. Having something on the shelf costs money, and the longer it sits there, the worse it is to have capital tied up in that stock. If a product is fast-moving, you can afford to make a smaller margin, but if it is slow-moving, it needs to have a bigger margin to achieve the same stock turn figures.

Auditing and Reviewing Processes

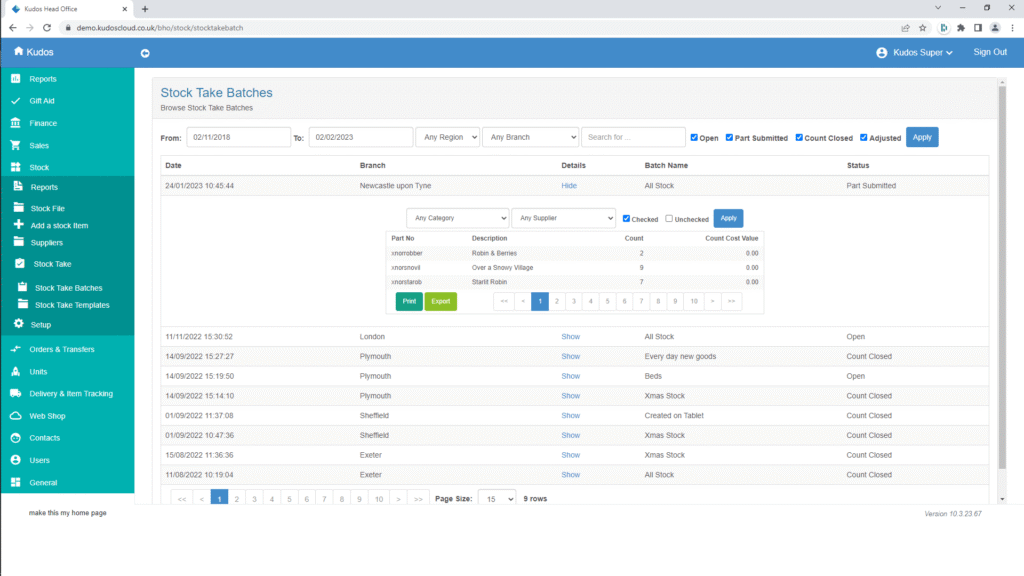

Stock control software reduces the need for resource-heavy manual stock takes as the software enables retail managers to speed up stock taking, monitor SKUs (stock keep units) and inventory, and run reports to capture quantities of stock sold.

Conducting Regular Audits and Cycle Counts

Implement regular stock audits and a review process to adjust stock control procedures and improve inventory management to ensure there is enough stock, in the right place and at the right time.

- Conduct regular stock taking audits and cycle counts to ensure inventory accuracy, identify discrepancies and minimise wastage/lost sales.

- Use real-time tracking stock control software to monitor sales, SKU stock movement, and identify areas for improvement.

- Prioritise regular stock taking for high turnover/high value stock, and only count slow-moving or dead stock annually. This reduces the workload but still has high accuracy.

Supplier Relationship Management

Provide your buyers and retail managers with software tools for better inventory management and a more accurate ordering system. A system such as Kudos makes inaccurate inventory counts a thing of the past, with accurate data you can rely on when reordering new stock and managing your supply chain. Improved relationships with suppliers may result in better terms, faster delivery times, and more flexible ordering quantities.

Partner with Reliable Suppliers

Partner with reliable suppliers to ensure consistent stock levels and reduce supplier lead times.

- Communicate regularly with suppliers to stay informed about lead times, order processing, and potential disruptions.

- Use stock control software that helps with order management and transfers between stores.

- Understand which suppliers give the best margins and which products are the best sellers.

Team Training and Education

Provide Training on Inventory Management Best Practices

By offering targeted training to your team on the best practices for effective inventory management, you can cut down on mistakes, make sure data entry is accurate, and make order processing simple. This training is all about giving your employees the skills and know-how they need to confidently use inventory management software and follow stock procedures, which in turn boosts productivity and accuracy.

- Provide employee training on inventory management best practices to reduce human error and ensure accurate data entry and efficient order processing.

Technology and Integration

Having a retail system that can be configured to reflect the way you trade is a massive advantage. Find a solution and stock control processes that provide reliable data in a format that you and your team can easily access and understand. Reporting by category and subcategory is essential to supporting the decisions small businesses and charities need to make in order to improve income.

Use Inventory Management Tools that Integrate with Other Solutions

- Use inventory management tools that integrate with other solutions, such as point of sale (POS) systems and accounting software.

- Consider implementing a mobile scanner system such as the Kudos Stock App to improve the speed of stock taking, inventory tracking and accuracy of count.

- Use inventory management software that provides real-time inventory tracking and automated reporting.

- Use reports and analytics to understand best-selling items, opportunities, and margins.

Reviewing and Adjusting

Manage excess or short stock levels by using inventory management software to track safety stock and committed stock levels, and receive alerts when stock levels fall below a certain threshold. Remember, collecting data is important, but data analysis and taking action are business critical.

Regularly Review and Adjust Your Stock Control Strategy

- Regularly review and adjust your stock control strategy to ensure optimal stock levels, meet market conditions and customer demand.

- Use software to track inventory movement and SKUs and identify areas for improvement.

- Use a safety stock policy to ensure optimal stock levels and hold emergency safety stock to mitigate stockouts and ensure consistent stock levels.

Conclusion

In conclusion, effective stock control procedures are vital for maintaining stock levels and meeting customer demand. Software like Kudos’ plays a crucial role in providing real-time tracking, automated reporting, and data analysis, which helps buyers make informed decisions.

Regular audits and forecasting are an essential part of efficient stock control, ensuring that stock levels match the sales curve and market demands. Building strong relationships with reliable suppliers also helps in maintaining consistent stock levels and reducing lead times. To minimise human error and improve accuracy, ongoing employee training and the integration of technology are also important.

Buyers should regularly review and adjust their stock control strategies to adapt to changing market trends and business needs. With this proactive approach, you can maintain optimal stock levels and support the growth and sustainability of the business.